Stunning Performance and Control: 2020 Shelby GT500 Achieves Supercar Acceleration with 760 Horsepower and 7- Speed Dual-Clutch Transmission

- Achieving 0-100-0 in 10.6 seconds, the Shelby GT500 sends drivers on a visceral driving experience typically reserved for exotic supercars thanks to its 760-horsepower engine, ultra-quick Tremec 7-speed dual-clutch transmission and the largest front brakes of any domestic sports coupe

- Its first-in-class 7-speed dual-clutch transmission delivers more consistent power and torque compared to manual transmissions, while its computer-controlled mechanism can upshift as quick as 80 milliseconds – faster than a blink of an eye – making it the most capable Mustang powertrain ever

- Shelby GT500’s five drive modes fully optimize the capabilities of the dual-clutch transmission and active chassis systems – from ultra-smooth road shifts in normal mode to forceful powershifts in drag mode – providing a personality for every type of performance driving

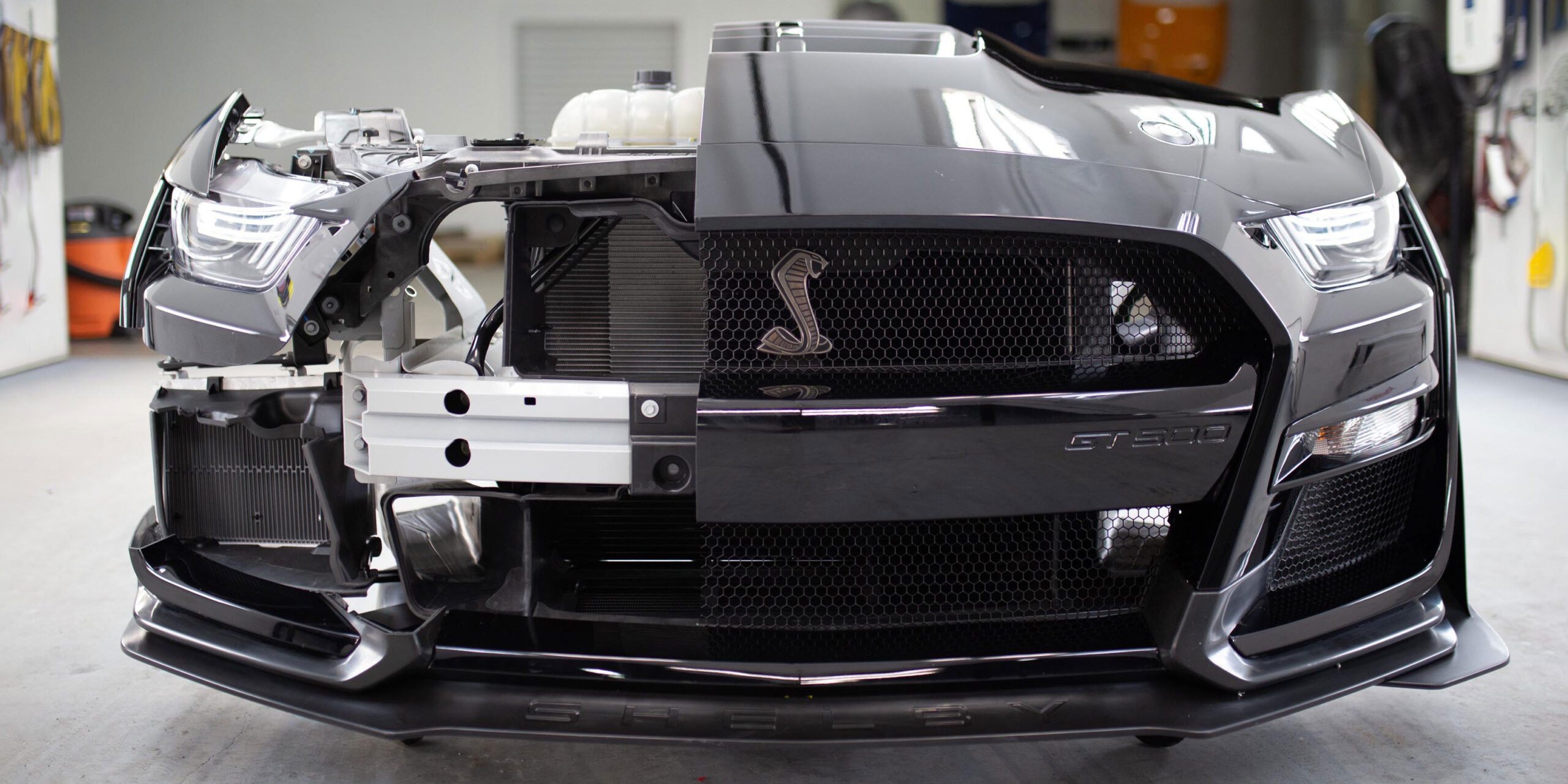

DEARBORN, Mich., Aug. 5, 2019 – As the most powerful street-legal Ford ever built, the all-new Mustang Shelby GT500 harnesses world-class muscle and powertrain technologies to attain supercar levels of performance. Its first-in- class 7-speed dual-clutch transmission, race-bred control strategies and advanced drive modes deliver a car that performs unlike any other domestic sports coupe.

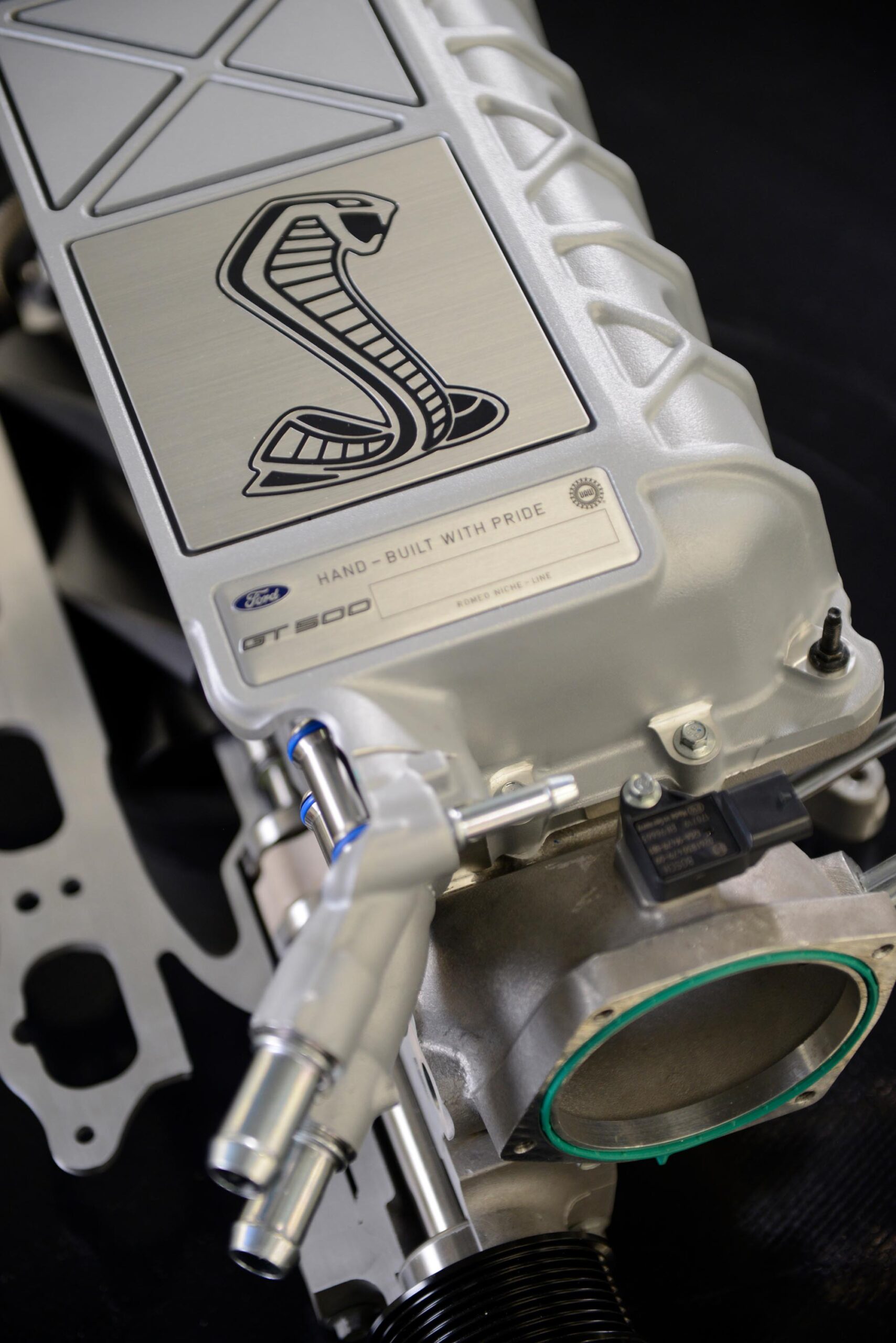

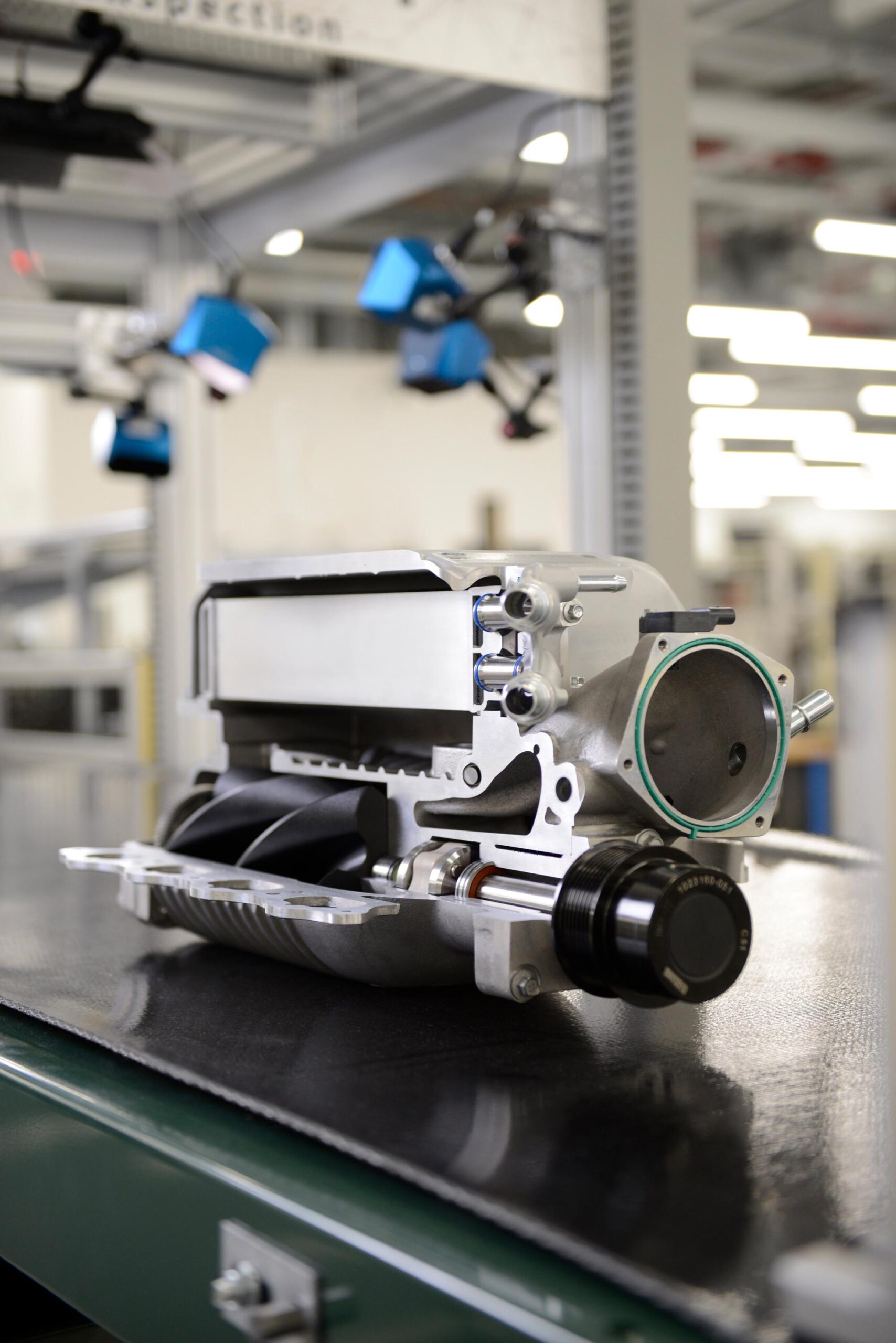

Its 760-horsepower 5.2-liter V8 engine is the most power- and torque-dense supercharged V8 in the world. With 625 ft.- lb. of torque funneled through a Tremec® TR-9070 DCT 7-speed dual-clutch transmission, the Shelby GT500 achieves a 0-100-0 in 10.6 seconds, thanks also to the largest front brakes of any domestic sports coupe (16.5-inch rotors) and available carbon fiber wheels, each wrapped in a Ford Performance-spec Michelin Pilot Sport Cup 2 tire.

Beyond the raw power and ultra-fast shifts, advanced control systems optimize the capabilities of the chassis and powertrain to create distinct drive modes – or personalities – to get the maximum performance from every aspect of the Shelby GT500 performance hardware.

“The range of brute-force drag acceleration, seamless road shifts and amazingly smooth shifts on the track further highlights how the soul of the Shelby GT500 is elevated in our most advanced Mustang ever,” said Ed Krenz, Ford Performance chief program engineer. “Effortlessly handling the 760 horsepower is our segment-first Tremec dual-clutch transmission, with an advanced control system that enhances GT500’s five drive modes to deliver a driving experience once reserved only for exotic supercars.”

DUAL-CLUTCH TRANSMISSION DELIVERS

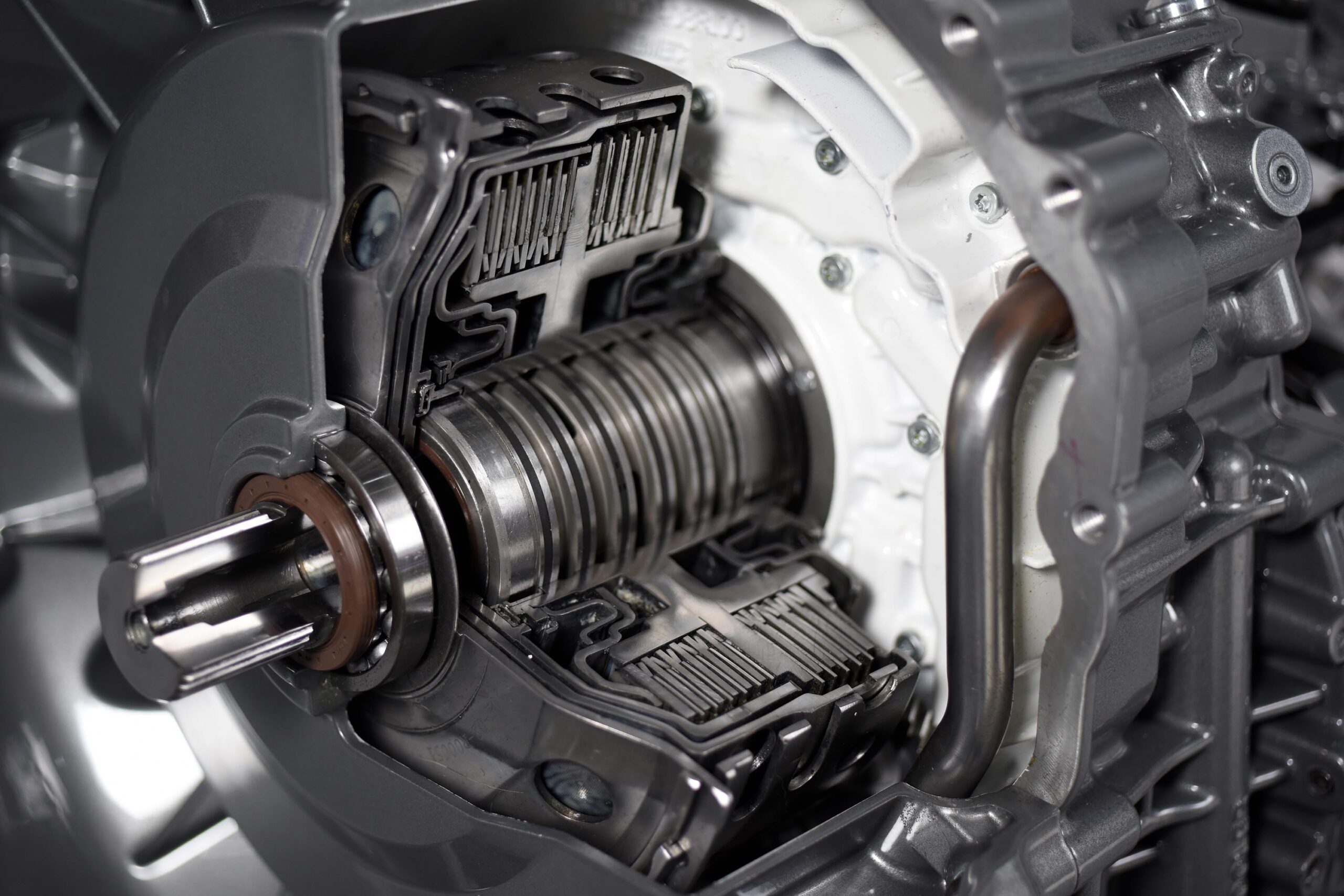

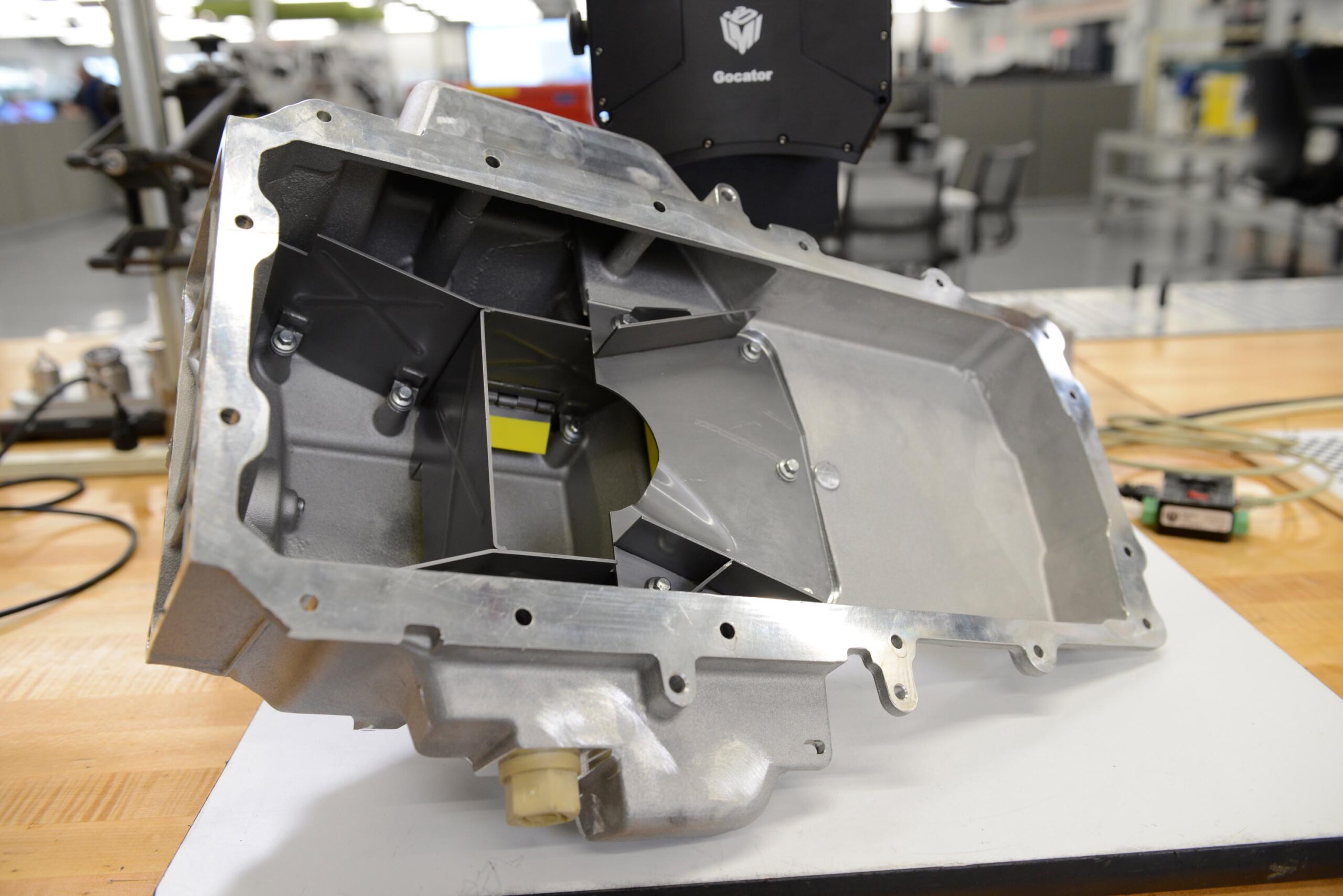

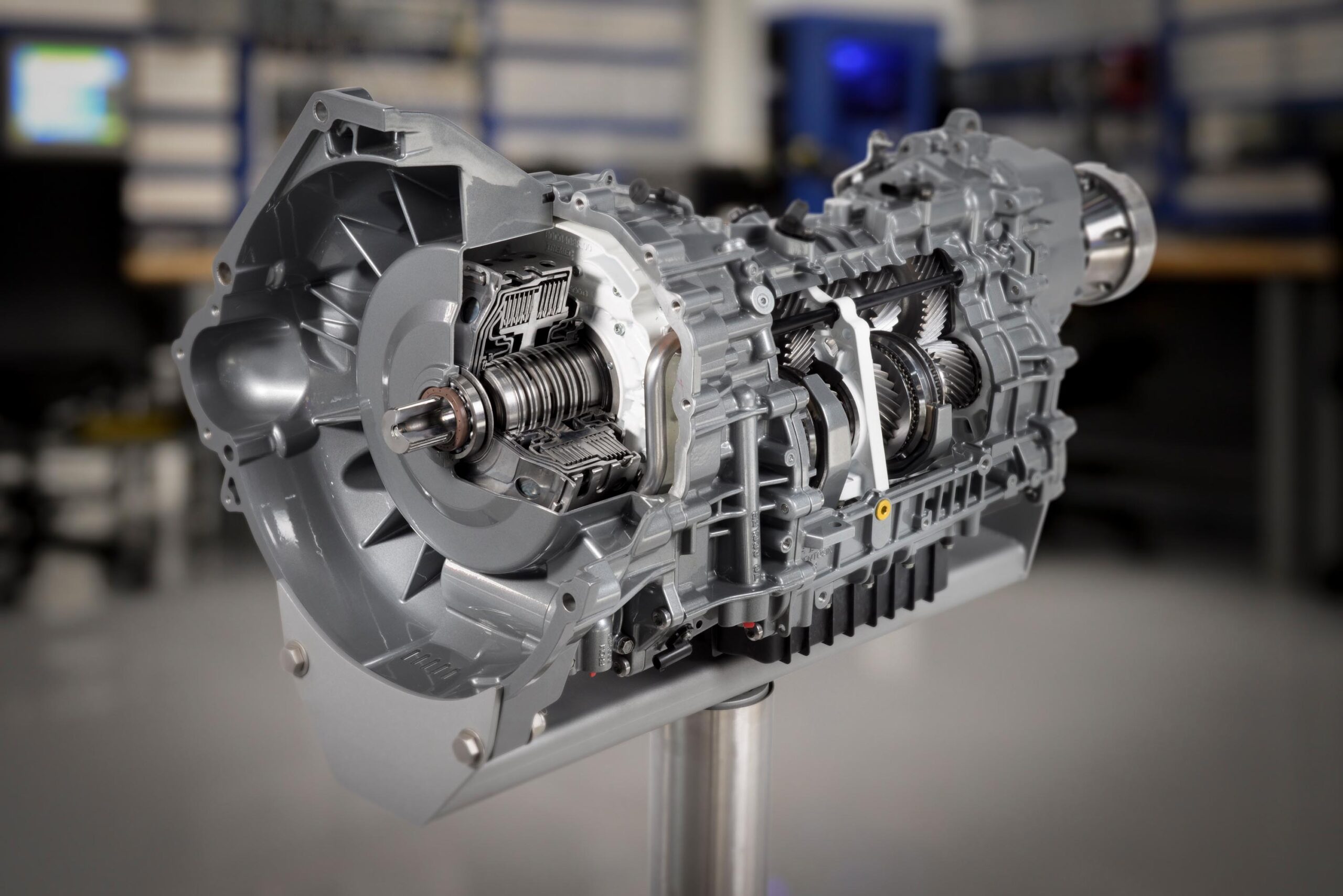

Applying 625 ft.-lb. of torque to the pavement effectively requires a transmission and driveline that can do more than just handle a massive amount of power. Ford Performance engineers collaborated with Tremec to design a gearbox that offers maximum driver control with stunningly fast shifting and greater performance across a wide spectrum of driving environments. The team’s “and” solution is the Tremec TR-9070 DCT 7-speed dual-clutch transmission.

“In many ways, this is like having two transmissions in one,” said Pat Morgan, Ford Performance powertrain manager. “On one hand, it enables performance at the outer reaches of straight-line quickness with minimal torque interruption, yet provides an incredible amount of finesse and control in track environments for maximum stability and predictability at the limits of lateral acceleration.”

To firmly and smoothly deliver torque, the TR-9070 DCT dual-clutch transmission has a novel wet clutch system with five friction plates in the odd-gear pack for a total of 155 square inches of surface area. In the even-gear pack, six friction plates provide 136 square inches of surface area. Transmission fluid is applied to the clutch surfaces only during thermal events for optimal cooling and minimal parasitic loss. Seven non-sequential helical forward gears with advanced triple cone synchros are carefully matched to the engine’s torque curve and are pre-selected by an electrohydraulic shift mechanism using energy-efficient low-leak solenoids that can execute shifts as quick as 80 milliseconds in sport mode.

Inside the control system, timing is everything. Shift points and clutch modulation are orchestrated by a computer- controlled mechatronics system that simultaneously reads dozens of vehicle and environmental factors – including engine and transmission rpm, driver input and g forces, and clutch and shift fork positions – to pre-select and engage the optimum shift for every driving situation. Steering wheel-mounted paddle shifters are direct-wired to the transmission to avoid CAN-bus vehicle communication system delays and initiate shifts as fast as 130 milliseconds, further enhancing responsiveness and connected feel.

“Contrary to popular belief, fast shifts do not always equate to better road performance,” said Morgan. “In every driving situation, we emulated what professional drivers do, whether it’s a smooth, precise heel-and-toe shift of a professional track driver or a much more forceful powershift like drag racers. We’ve designed the perfect shift every time.”

DRIVE MODES ADD MORE PERSONALITY

The 2020 Shelby GT500 has five drive modes that further enhance the driver experience with a flick of the console mounted mode switch. It instantly changes the car’s personality from a moderated “normal” car to a “track” master with more aggressive throttle responsiveness and gear selections. The system changes nearly every aspect of the car’s behavior, including ride dampening, stability control, antilock brake modulation and steering feel – even the sound and instrument panel change. Inside the TR-9070 DCT dual-clutch transmission, drive modes influence transmission shift points and feel.

In normal mode, the system selects gears and shift timing for moderated, everyday driving and seamless shifting. In sport mode, shift character changes, slicing shift timing by roughly 20 percent while throttle tip-in is more responsive and rpm ranges extend longer into the maximum torque curve.

Selecting track or drag mode further changes the shift characteristics to pure performance. For maximum straight- line quickness, gear changes use “over-torque” shifts for uninterrupted power delivery, similar to powershifts that give an extra torque hit in between upshifts. Take the Shelby GT500 into a turn, however, and the transmission immediately adapts with smooth, quick and seamless shifts to ensure maximum lateral g cornering by minimizing driveline disturbances.

Drive modes aside, an rpm-selectable launch control and electronic line lock through Track Apps® enable synchronous powertrain strategies that deliver optimum quarter-mile runs, while an always-on pseudo launch control enables spirited launches at any time without having to select a drive mode.

“Every aspect of the Shelby GT500 driving experience changes with the mode – be that the throttle responsiveness and snap of the shifts you feel in the seat of your pants, or the ‘pop and burble’ of the exhaust in performance modes. It’s a full multisensory visceral experience,” said Morgan.

Power output is transmitted to the 3.73:1 Torsen limited-slip independent rear suspension via a carbon fiber driveshaft for reduced rotational mass and torsional distortion, plus larger half shafts and a redesigned rear suspension hub for added strength.