McLaren Elva revealed: extreme new roadster designed for Ultimate driving enjoyment celebrates McLaren’s relentless pioneering spirit

- McLaren Automotive acquires rights to the Elva name for new Ultimate Series roadster

- Open-cockpit two-seater celebrates Bruce McLaren-designed 19605 McLaren-Elva sports cars that embody McLaren’s pioneering design and engineering principles

- The lightest1 road car ever from McLaren Automotive, with bespoke carbon fibre chassis and body, unique carbon fibre seats and sintered carbon ceramic brakes

- Unparalleled driver engagement and Ultimate driving enjoyment, with absence of roof, windscreen and windows ensuring incredibly immersive and enthralling experience

- McLaren Active Air Management System (AAMS) is world-first; shelters occupants by manipulating air flow while retaining their connection to the elements

- Homologated for all major markets; fixed windscreen derivative also available

- New and unique McLaren ‘blurred boundaries’ design principle sees carbon fibre bodywork wrapping into the open-air cabin as exterior flows into the interior

- Breathtaking performance from 804bhp, twin-turbocharged McLaren V8: O-62mph in under three seconds; 0-124mph quicker than the McLaren Senna, at just 6.7 seconds

- Innovative Inconel and titanium quad-exit exhaust delivers unique soundtrack; enhances engine power by reducing back pressure

- McLaren expertise in vehicle dynamics showcased: active aerodynamics; state-of-the-art, linked-hydraulic active suspension; electro-hydraulic steering for purest feedback

- Just 399 examples of new McLaren Elva available to customer order, from $1,690,000 (USD); final price will depend on level of personalization by McLaren Special Operations (MSO)

McLaren Automotive today reveals its new Ultimate Series roadster, the McLaren Elva. As the brand’s first open-cockpit road car, the Elva adds a new dimension to the range-topping Ultimate Series lineage. Like its McLaren PlTM, McLaren Senna and Speedtail predecessors, volume of the new McLaren Elva will be strictly limited: just 399 are being offered for customer order.

The Elva name celebrates the renowned Bruce McLaren-designed WA and McLaren-Elva M1A[Mk|], MlB [Mk II] and MlC [Mk III] of the 19605. Produced as ’Customer’ versions of the innovative and exciting Group 7 McLaren race cars, the McLaren—Elva sportscars embodied many of the pioneering design and engineering principles that are integral to the McLaren road cars produced today.

“McLaren continues to push the boundaries of supercar and hypercar development in pursuit of outstanding and unparalleled driving experiences for our customers, and the McLaren Elva epitomizes that pioneering spirit. The McLaren-Elva M1A [Mk1] and its successors are in many ways the true spiritual forerunners of today’s McLarens – superlight, mid-engined cars with the highest levels of performance and dynamic excellence. It’s fitting that the new McLaren Ultimate Series roadster – a uniquely modern car that delivers the ultimate connection between driver, car and the elements and with that new heights of driving pleasure on road or track – acknowledges our rich heritage with the Elva name.”

Mike Flewitt, CEO, McLaren Automotive

The new McLaren Elva is a ferociously fast open-cockpit; an extreme two-seater with a bespoke carbon fibre chassis and body but no roof, no windscreen and no side windows. With every sensory input heightened, this is a car that exists to provide unparalleled driving pleasure on road or track.

A 4.0-liter, twin-turbocharged McLaren V8 from the same family of engines that powers the McLaren Senna and Senna GTR combines with the lightest vehicle weight1 of any road car produced by McLaren Automotive to give the superlight new Ultimate Series roadster truly breathtaking performance across the board, with extraordinary levels of acceleration, agility and driver feedback.

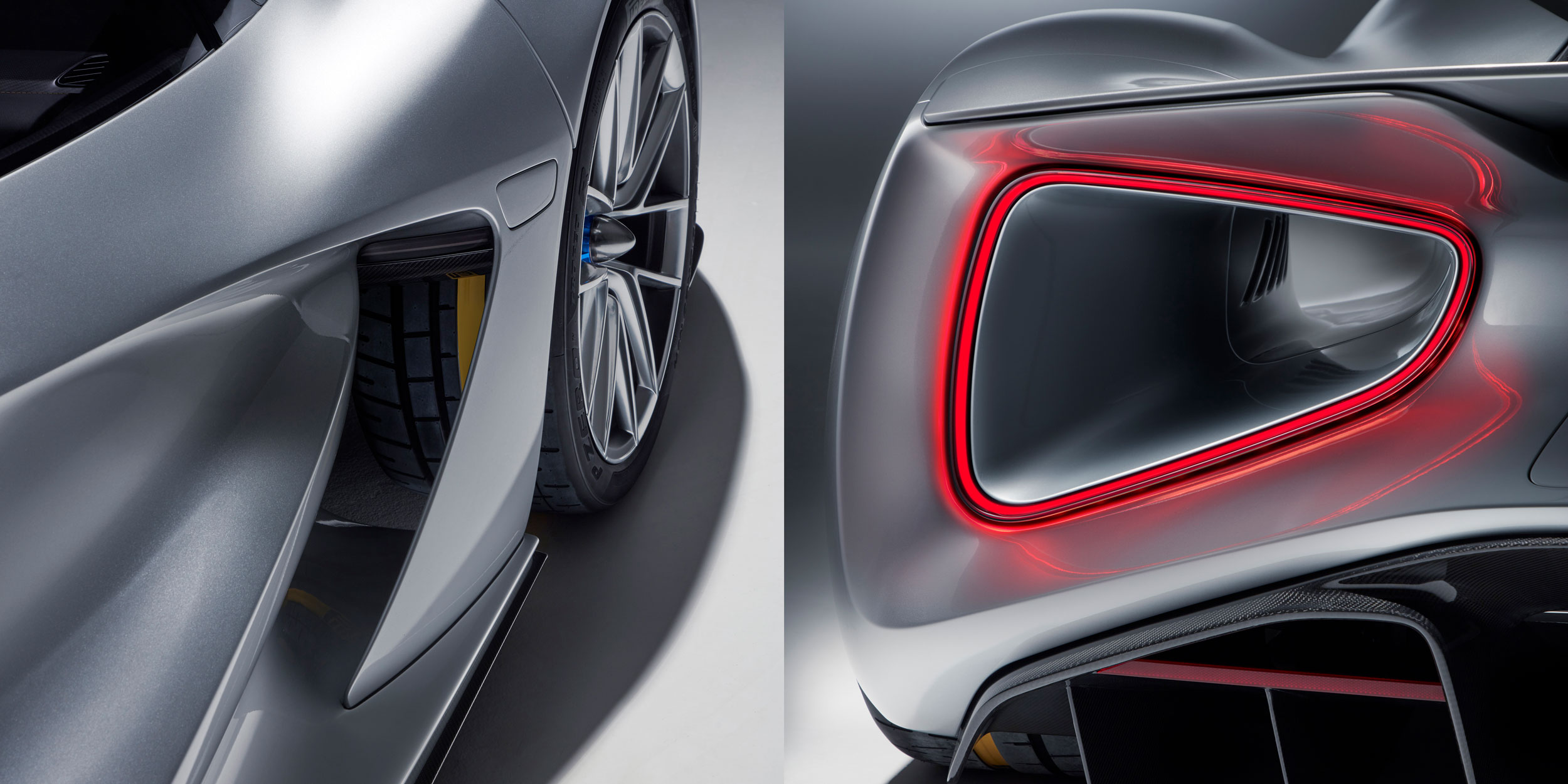

The appearance of the McLaren Elva is as striking and unique as the driving experience. The low nose and pronounced front fender peaks provide visual drama and at the same time enhance forward vision. Large, carbon fibre rear fenders flow from the front of the door to the rear deck, while the height of the twin rear buttresses is minimized by using a deployable roll-over protection system.

Helmets can be worn if preferred, but the form and sculpture of the upper cabin wraps around the driver and passenger to provide a secure environment. A fixed windscreen derivative of the car is also available for most markets as a factory option.

WORLD-FIRST IN AERO PROTECTION

A true connection with the elements is integral to the McLaren Elva driving experience but that hasn’t stopped McLaren innovating a world-first, the Active Air Management System (AAMS) to enhance driving pleasure. The system channels air through the nose of the Elva to come out of the front clamshell at high velocity ahead of the occupants before being directed up over the cockpit to create a relative ‘bubble’ of calm. The system comprises a large central inlet situated above the splitter, a front clamshell outlet vent and a discreet carbon fibre deflector that raises and lowers vertically; when the AAMS is active, the deflector is deployed at the leading edge of the bonnet outlet, rising 5.9in into the freestream to create a low-pressure zone at the vent.

The vented air is directed through a 130-degree radius, using a network of transverse and longitudinally mounted carbon fibre vanes across the bonnet outlet; distributing the airflow both in front of and along the side of the cabin further assists air management in the cabin environment. At urban speeds, when the level of airflow into the cabin means the AAMS is not needed, the system is inactive. As vehicle speed increases, the AAMS automatically deploys and remains active until speed reduces, at which point the deflector retracts. The system can also be button-deactivated by the driver.

AESTHETIC AND TECHNICAL DESIGN IN HARMONY

McLaren’s design philosophy intrinsically links aesthetic design and technical design, rather than separating the disciplines of design and engineering as is commonplace in the automotive industry. The AAMS is an example of the results of this harmonious approach, being perfectly integrated within the aerodynamic and cooling functionality of the McLaren Elva.

When the AAMS is inactive, the central duct is sealed, diverting air flow into the low-temperature radiators and increasing their cooling efficiency. To provide optimal packaging conditions for the AAMS, the McLaren Elva features twin low-temperature radiators (LTRs) positioned ahead of each front wheel. The new cores used in these LTRs contribute to the engine’s 804bhp power output by reducing charge air temperature and also cool the oil in the seven-speed seamless shift transmission.

In addition to housing the AAMS, the front clamshell features deep contours that guide air into a discreet duct in the leading edge of each carbon fibre door – notably the lightest that McLaren has ever created. This captured cooling air is then directed into the two rear-mounted, powertrain-cooling, high- temperature radiators (HTRs) located just ahead of the rear wheels. A second, lower duct that starts inside the front wheelarch also channels air through the bodyside to the HTRs, which are additionally fed through the visible main side intakes. Intakes on the rear of each buttress channel combustion air into exposed air filters under the tonneau, which feed the carbon fibre engine plenum.

The trailing edge of the bodywork features a full—width active rear spoiler, the height and angle of which are adjusted simultaneously to optimize aero balance. Airbrake functionality improves braking from high speeds, the range of operation varying according to whether the AAMS is active. The rear diffuser works in conjunction with the active rear spoiler. The McLaren Elva has a completely flat underfloor until the point by the rear axle at which the diffuser starts and increases in height to accelerate air out from under the vehicle. The diffuser features vertical ’fences’ to guide the airflow without reducing the air evacuation path and these combine with the rear bumper side extensions to further improve the aerodynamic efficiency.

DESIGNED TO DELIVER AN ELEMENTAL DRIVING EXPERIENCE

“Our mission with the McLaren Elva was to create an open-cockpit, two-seat roadster that delivers the most elemental of driving experiences. Formula 1-inspired shrink-wrapped volumes create a technical sculpture that is as striking as it is remarkable, the exterior flowing into the interior in a stunning example of a new and unique McLaren ‘blurred boundaries’ design principle that has allowed us to seamlessly bring the outside in to further enhance driver engagement while remaining true to our philosophy of making no compromises.”

Rob Melville, Design Director, McLaren Automotive

Highlighting the intensity of the driving experience through the direct connection to the elements, there is no clear demarcation between the exterior of the McLaren Elva and the interior. The uppermost sections of the carbon fibre doors simply curve over and flow down into the cabin, the light, stiff and strong composite material providing the perfect properties to form such enticing shapes and forms. Complementing this unique design feature, the buttresses behind the driver and passenger also flow into the cabin behind the seats. While ensuring the driver and passenger remain exposed to the elements, the sculpture of the wraparound upper cabin environment enhances the feeling of security and protection within a cocooned interior.

A spar of carbon fibre additionally sweeps down from between the buttresses and runs between the driver and passenger seats to support a central armrest and cradle the engine start button and the controls for Drive, Neutral and Reverse functions. The seats themselves are of a bespoke design, with a new lightweight carbon fibre shell that not only supports the head, shoulder and back area of the occupants, but works seamlessly with the upper shape of the cabin. The lower area of each seat is marginally shorter than a conventional McLaren seat, allowing enough space within the footwells for driver or passenger to stand should they want to in order to enter or leave the vehicle. The seats are available with different upper and lower colors and materials, creating a contrast between the exposed upper section and cocooned lower section. Six-point race harnesses can be selected should the customer wish to use the McLaren Elva on track.

Ahead of the driver and passenger, the view forward is unprecedented, with the dashboard seamlessly flowing down into the cabin and around to meet the swooping doors. The shapes are organic and natural – almost pebble-like – with the only interruption to their smooth forms the instrument cluster that stands proud, moving with the steering wheel to optimize visibility of vehicle data for the driver.

In a first for McLaren, the controls for the Active Dynamics functions are integrated into the instrument cluster; set either side of the binnacle, the dynamic mode switches are situated close to the gearshift paddles and their operation does not require the driver to remove their hands from the steering wheel. Additional functionality is accessed through the centrally-mounted 8-inch high-resolution touchscreen monitor; a hub for all the vehicle’s functions, this brand-new interface features an edgeless-glass screen and a side-mounted control dial. This Central Infotainment Screen has been developed to allow the driver to run multiple applications simultaneously, akin to a smartphone, flicking through them on a vertical carousel. The system shows a range of applications on the screen, including satellite navigation, McLaren Track Telemetry, rear-view camera and climate control. The screen is mounted on a lightweight carbon fibre arm and tilted towards the driver.

Stowage space is offered beneath the rear tonneau. Crafted from carbon fibre, the curving single-piece panel is operated manually and secured with soft-close latches. Elegant and lightweight, it further reduces weight at one of the highest points of the McLaren Elva. The compartment under the tonneau has space for helmets and also houses the porthole-like panels that showcase the two visible air filters – a fine example of the McLaren design principle of exposing functional engineering.

A portfolio of bespoke interior materials will be available for the new McLaren Elva, allowing customers to personalize their car according to its intended use. Interior leathers in a range of finishes and levels of protection – including an Enhanced Full Aniline leather with a second protective layer to the leather – have been developed to meet the requirements of the open-cockpit car. Additionally, a new technical interior material, Ultrafabric, is another innovation for the car. This breathable synthetic material offers a very different proposition to leather; comprising four layers, the outer two surfaces providing durability and moisture resistance and the inner layers adding a reinforced rayon-fibre base and cushioning, the Ultrafabric helps to ‘grip’ you in the seat.The McLaren Elva does not have an audio system as standard (in line with the determination to minimize vehicle weight) but customers can specify at no additional cost a bespoke system. Further non-cost options include 5-Spoke Super-Lightweight forged alloy wheels in lieu of the 10-Spoke Ultra- lightweight wheels fitted as standard; track-focused Pirelli P ZeroTM Corsa tires rather than Pirelli P ZeroTM tires; and a vehicle lift system.

Additional personalization options available through McLaren Special Operations (MSO), the bespoke division of McLaren, include interior color choices for the Ultrafabric and leathers; virtually limitless exterior paint colors and almost anything else between a delicate pin-stripe on the wheels and a blended full-body ‘contour’ or ‘velocity’ finish that mixes multiple colors across the length of the vehicle. Any selection is individually hand-painted by MSO’s highly experienced craftspeople.

Alternatively, customers can select a Gloss Visual Carbon Fibre Body, which exposes not only the carbon fibre body panels, but also the perfectly aligned twill of the composite material. This can be further enhanced with a range of color tints. McLaren Special Operations can also develop a bespoke tint for the exterior or interior carbon fibre.

The McLaren Elva can also be personalized with 18ct white gold or platinum badges that feature a TPT inlay. An automotive world-first when introduced on the McLaren Speedtail, thin-ply technology carbon (or TPT for short) is formed from multiple ultra-thin carbon layers just 30 microns in depth. Positioned at a 45-degree angle, when gently milled they expose a stratified, shimmering surface that resembles flowing water. Additionally, MSO offers a 24ct gold engine bay heat shield.

The new Ultimate Series McLaren is priced from $1,690.000, the final specification is determined by customer choice, with infinite possibilities in terms of personalization by McLaren Special Operations (MSO) to ensure each Elva is unique.

ULTIMATE, IMMERSIVE PERFORMANCE

“The McLaren Elva is a true Ultimate roadster; it exists purely for the pleasure of driving, to deliver an enthralling and immersive experience born from the ultimate connection between the car, the driver and the elements. The lightest road car we’ve ever built at McLaren Automotive, the Elva is incredibly agile and ferociously fast, its 804bhp twin-turbocharged V8 engine providing breathtaking performance that heightens every sense. “

Andy Palmer, Vehicle Line Director – Ultimate Series, McLaren Automotive

The core of the McLaren Elva is – as with every McLaren road or race car since 1981 – a carbon fibre monocoque. This state-of-the-art ‘tub’ is incredibly strong and stiff, and its inherent properties mean an open-top roadster does not require any additional strengthening as would be the case with a vehicle built from aluminum or steel. Conversely, despite its rigidity, carbon fibre is also incredibly light, helping to reduce the overall vehicle weight.

To that effect carbon fibre has also been used extensively throughout the McLaren Elva. The entire body is carbon, and McLaren has pushed the limits of the material to not only create incredible sculpted forms, but to also reduce weight. The front clamshell, for instance, is just 1.2mm thick and meets all of McLaren’s structural integrity targets – yet it forms an astonishing one-piece panel that wraps around the entire nose of the vehicle and provides a clean, uninterrupted vision without any panel joins. Perhaps even more impressive are the body side panels, which are each over ten feet long and stretch from the front wheels, past the side intakes, around the rear tonneau cover and all the way until the active rear spoiler.

Each door is constructed entirely of carbon fibre and features a single-hinge design, mounting to the vehicle just behind the front clamshell. The doors operate in a Dihedral function, a McLaren trademark. The floor within the McLaren Elva is exposed carbon fibre, once again highlighting the weight saving throughout. Practicality is enhanced with the use of non-slip material at selective points, or bespoke floor mats if preferred.

Carbon, too, forms the core of the braking system which is the most advanced ever fitted to a McLaren road car. Each sintered carbon ceramic disc measures 390mm and takes significantly longer to produce than a conventional carbon ceramic disc, but the resultant material is much stronger and has improved thermal conductivity. This allows the front brake discs in particular to be reduced in size, benefitting unsprung mass while still maintaining performance. Cooling requirements are lessened, reducing the brake ducting needed, which further reduces weight and improves aerodynamic efficiency. The braking system was first introduced on the McLaren Senna but is enhanced for the Elva with the addition of titanium caliper pistons which save a total of 1kg across the vehicle.

Such braking performance is essential because of the performance delivered by the 804bhp, 590ft-lb 4.0-liter, twin-turbocharged McLaren V8 that powers the Elva. From the same family of engines that powers the McLaren Senna and Senna GTR, it features a flat-plane crankshaft, dry-sump lubrication and lightweight connecting camshafts, rods and pistons that reduce mass in the powertrain. Power is directed to the rear wheels through a seven-speed seamless-shift gearbox, and working in conjunction with a launch control function, the performance is breathtaking: 0-62mph is reached in less than three seconds, while the McLaren Elva is quicker than the McLaren Senna to 124mph at just 6.7 seconds2.

The increased power output is achieved through an optimized exhaust system with reduced back pressure, and improved LTR performance that reduces charge air temperatures. The exhaust itself is an intricate and lightweight titanium and Inconel system, with two lower exits flanking a twin top- mounted exit. In a first for a McLaren road car, the titanium exhaust finisher is created using 3D printing technology to form the unique shape. The exhaust note of the Elva is clean, crisp and unmistakably powerful, as befits an Ultimate Series McLaren.

The power of the McLaren Elva is complemented by a chassis set-up that maximizes agility and driver engagement and feedback, enhancing the incredibly immersive and enthralling driving experience. Electro-hydraulic steering provides the purest feedback, as expected of a car when the open-cockpit design positions the driver so close to the elements. State-of-the-art McLaren linked-hydraulic fully active suspension offers a staggering breadth of ability on all road surfaces, with both unique software settings and bespoke springs and damper valving matched to the extremely light overall vehicle weight.

Accessed through the Adaptive Dynamics Controls, the Comfort, Sport and Track modes for the Handling and Powertrain change the driving characteristics to suit driver mood or environment. Those wishing to explore the full performance of the Elva can adjust the level of available wheelspin and oversteer with three Electronic Stability Control (ESC) modes or utilize Variable Drift Control (VDC). Unique to McLaren, VDC unlocks new levels of driving freedom and excitement. Track-focused Pirelli P ZeroTM Corsa tires are available as a non-cost option.

MCLAREN M1A: SUPERLIGHT SUCCESS DESIGNED AND ENGINEERED BY BRUCE MCLAREN

Designed by Bruce McLaren, the McLaren M1A was superlight, weighing just 1,215lbs with a lightweight but very rigid and strong chassis – in this case a tubular steel spaceframe. Made using both round and square section tubes, the chassis was reinforced with magnesium alloy sheeting, bonded and riveted in place as a stressed undertray.

A 340bhp Oldsmobile 4.5-liter V8 was mid-mounted. Suspension was cutting-edge for the mid-1960s: fully independent, with unequal length wishbones, anti-roll bar and adjustable coil springs and shock absorbers at the front and reversed lower wishbones with similar coil springs at the rear. The molded resin bodywork – again light in weight – was visually very distinctive, with the M1A and McLaren-Elva M1A [Mk I] both having a pointed nose and absence of any lip at the rear. The styling of the later McLaren-Elva M1B [Mk II] and M1C [Mk III] was more muscular, but from the outset the cooling ducts and side fuel tanks integrated into the design were laying down the principles of ‘form follows function’ and ‘everything for a reason’ to which McLaren still rigorously adheres.

When the M1A raced in September 1964 at the Canadian Sports Car Grand Prix – the forerunner to the famous Canadian-American (Can-Am) Challenge Cup that McLaren drivers won for five consecutive years from 1967 to 1971 – it took third place overall but was the fastest car on the circuit, equaling the lap-record four times and breaking it seven more.

Demand for customer cars after such an impressive showing was immediate, but with just seven employees at McLaren – all of whom were engaged in building team racing cars – the only solution was to outsource production. Frank Nichols of Elva Cars Ltd, a small, specialist sportscar manufacturer based in Sussex, UK, proposed that he would build replica versions of the M1A and in November 1964, McLaren and Elva’s parent company agreed terms to proceed.

The McLaren-Elva M1A [Mk I] developed into the McLaren-Elva M1B [Mk II] and then the McLaren-Elva M1C [Mark III], the cars competing in privateer hands while in parallel the status of the McLaren brand grew as it moved towards becoming a major force in top-level motorsport.

The McLaren-Elva M1B [Mk II] attracted the attention of American automotive magazine Road & Track, which in July 1966, declared it, “the fastest car we’ve ever tested (and) an example of the latest thinking in sports/racing cars.” The final iteration of the series, the McLaren-Elva M1C [Mk III], was introduced in 1967, by which time the McLaren works team had moved into a new era with the M6A.

“We are delighted to have gained the rights to the Elva name for an extraordinary new roadster that adds a new dimension to the McLaren Ultimate Series while tracing its lineage back to the sportscars that laid the foundations for McLaren’s success. The McLaren-Elva M1A [Mk I] and its immediate successors not only set standards on the track but also established the pioneering design and engineering principles that remain at the heart of our brand; what better way to celebrate that than by bringing the Elva name right up to date.”

Mike Flewitt, CEO, McLaren Automotive

Customer deliveries of the McLaren Elva are scheduled to begin towards the end of 2020. Additional information about the new Ultimate Series roadster can be found at https://cars.mclaren.com/en/ultimate-series/mclaren-elva