Bugatti Dimple Airscoop – A new invention for enhanced Aerodynamics

Bugatti presents world-first used for the Bolide, the race track-focused hyper sports car.

Molsheim, 10 December 2020. The French luxury car manufacturer presented an extreme technological concept a few weeks ago – the Bugatti Bolide1. The hyper sports car is a vehicle developed around the iconic 8.0 litre W16 engine, with 1,850 PS2 and weighing 1,240 kilograms3. This ensures an incredible weight-to-power ratio of 0.67 kg/PS, a top speed of well over 500 km/h4, perfect handling and maximum agility.

The Bolide is packed full of technological innovations. Chief among which is the Dimple Airscoop – a new technology for which Nils Ballerstein submitted a patent application a few weeks ago. Since the beginning of 2020, the engineer has been preparing a doctoral thesis project to develop a special morphable outer skin for the New Technologies department at Bugatti – and this has now been used for the first time in the Bugatti Bolide. The idea for the invention began in 2019, while Ballerstein was doing his master’s degree thesis. The young engineer was undertaking research for Bugatti, looking at new 3D-printed brake callipers made of titanium which cooled water as it flowed through. In order to improve the heat transfer and dissipate heat more selectively, he used a dimple pattern inside the channels. The rounded dents in the boundary layer produce turbulence – similar a golf ball. The result was that the fluid mixes better in the channels – and the temperature in the brake calliper drops. “I was positively surprised when I saw the results with the surface patterns. I then wondered whether the same effect couldn’t be achieved with air flow,” says Ballerstein.

Same advantages as golf ball design

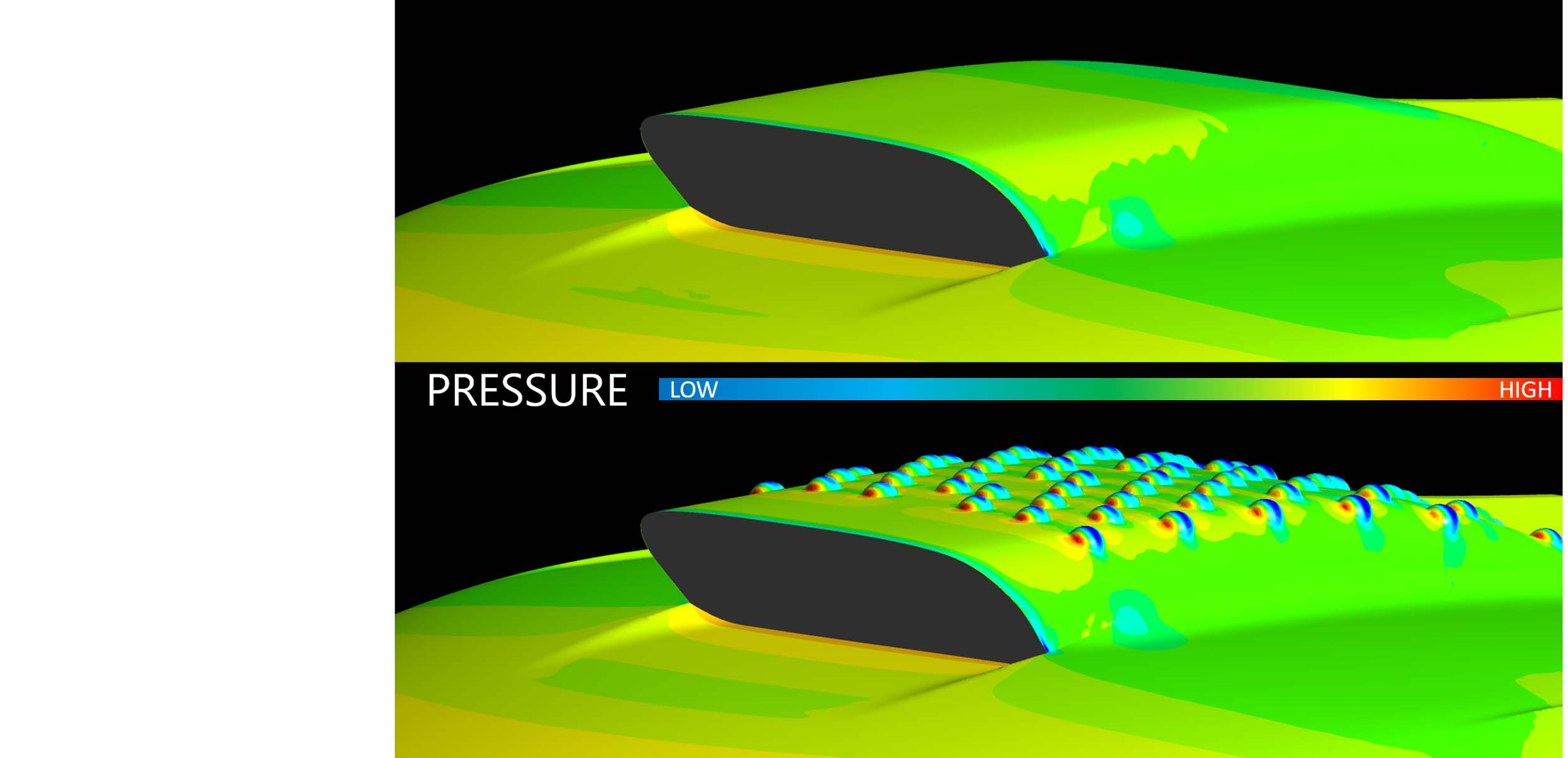

For non-scientists, the effect of the aerodynamic design is similar that that of golf balls: the dimples on the surface minimise air drag to such an extent that the ball travels about twice as far with the same impact force compared to an identical golf ball without the dimples. The same principle applies: the dimples create turbulence on the surface of the golf ball so that air adheres better to the surface, thereby reducing the vortex flow in the slipstream of the ball and subsequently also the drag.

Nils Ballerstein simulated test objects with dimple patterns in order to establish a factual basis to underpin his idea. After completing his master’s thesis, he stayed on with Bugatti while also starting his doctorate at the Institute of Aircraft Design and Lightweight Structures at the “Technische Universität” (Technical University) Braunschweig. He sees the Bolide project as a perfect way to advance his idea. “Everything about the Bolide is exceptional and extreme. The dimples further improve the car’s already excellent aerodynamics, thereby increasing agility and efficiency,” explains Frank Götzke, Head of New Technologies at Bugatti.

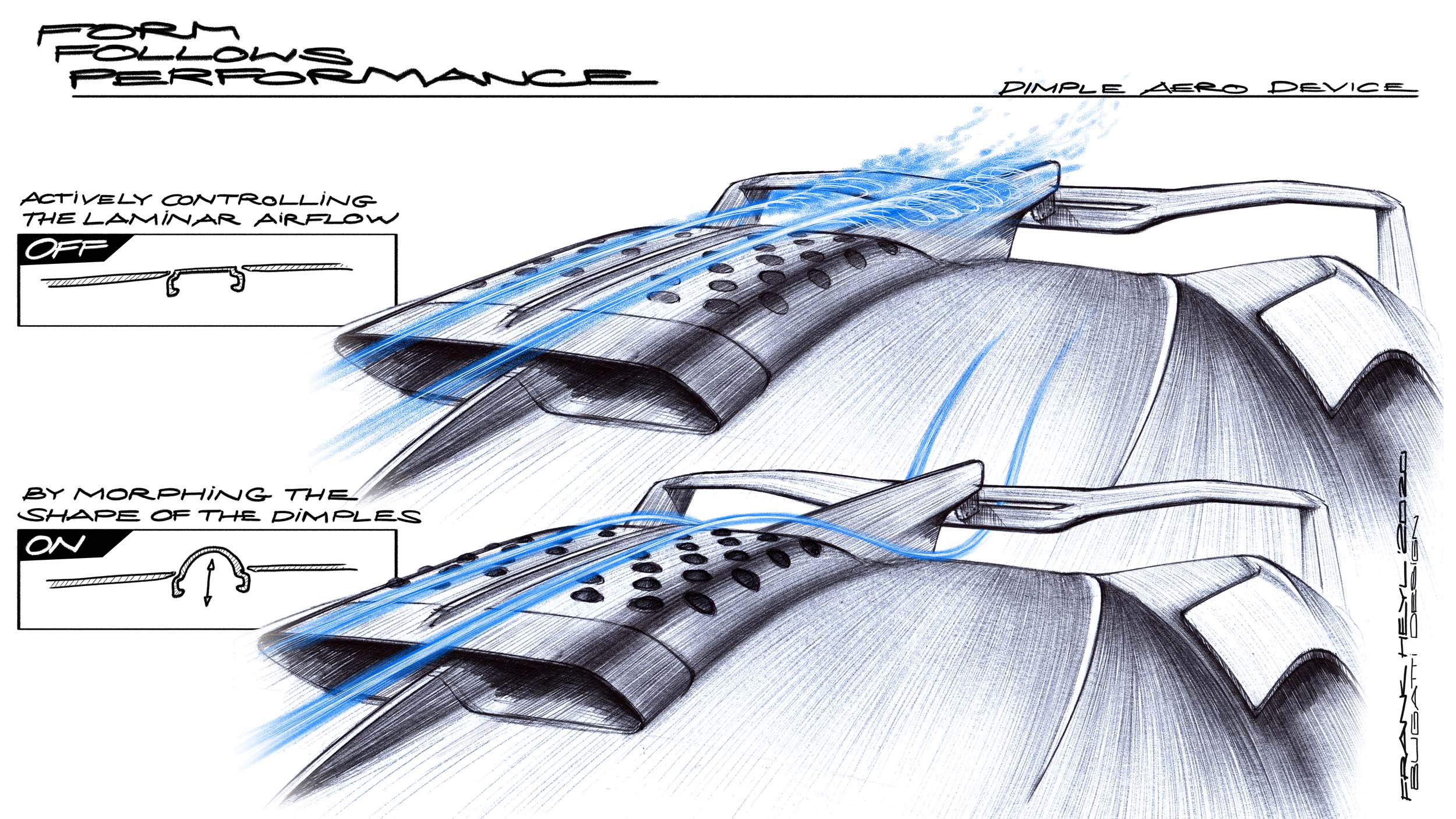

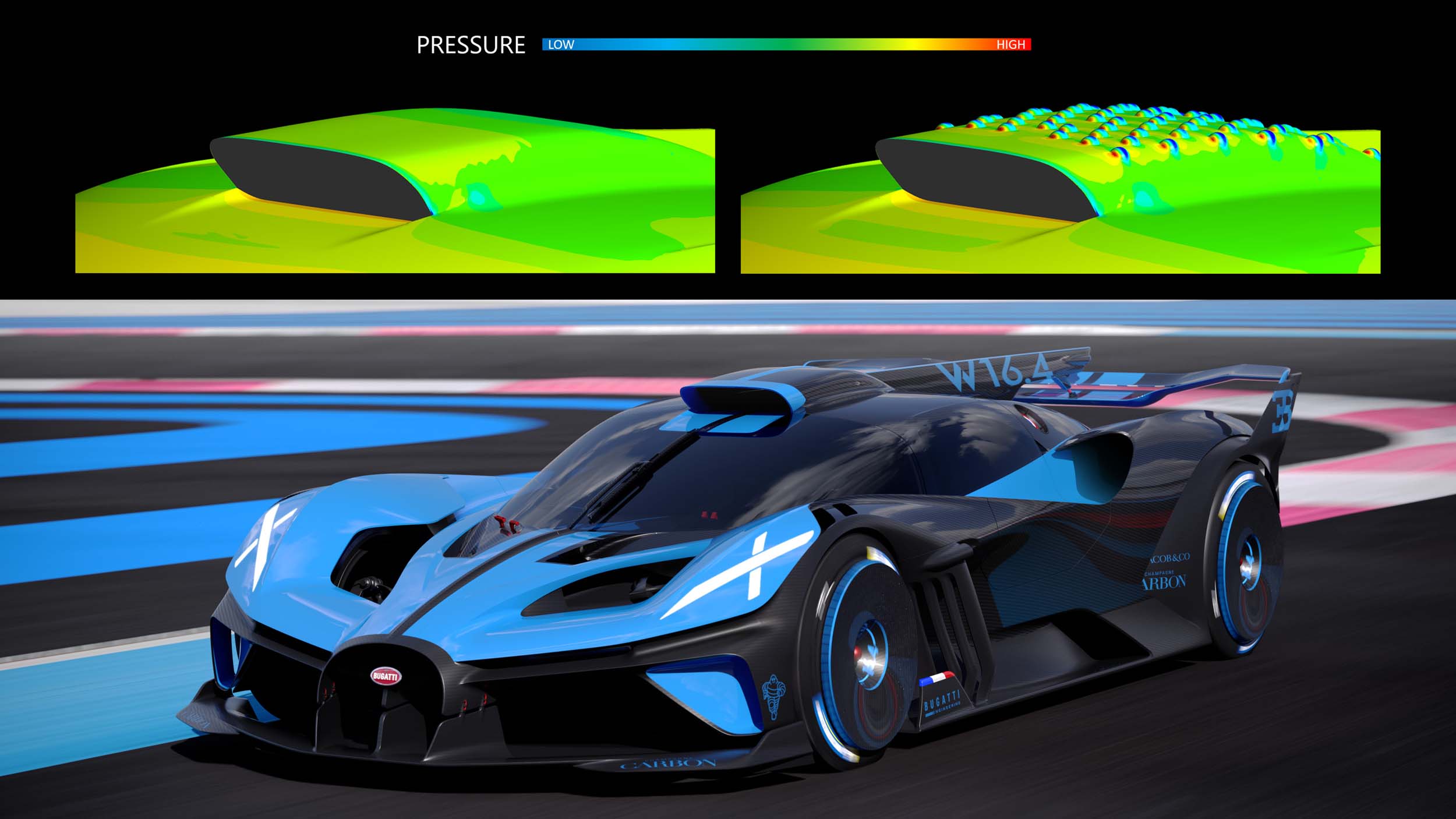

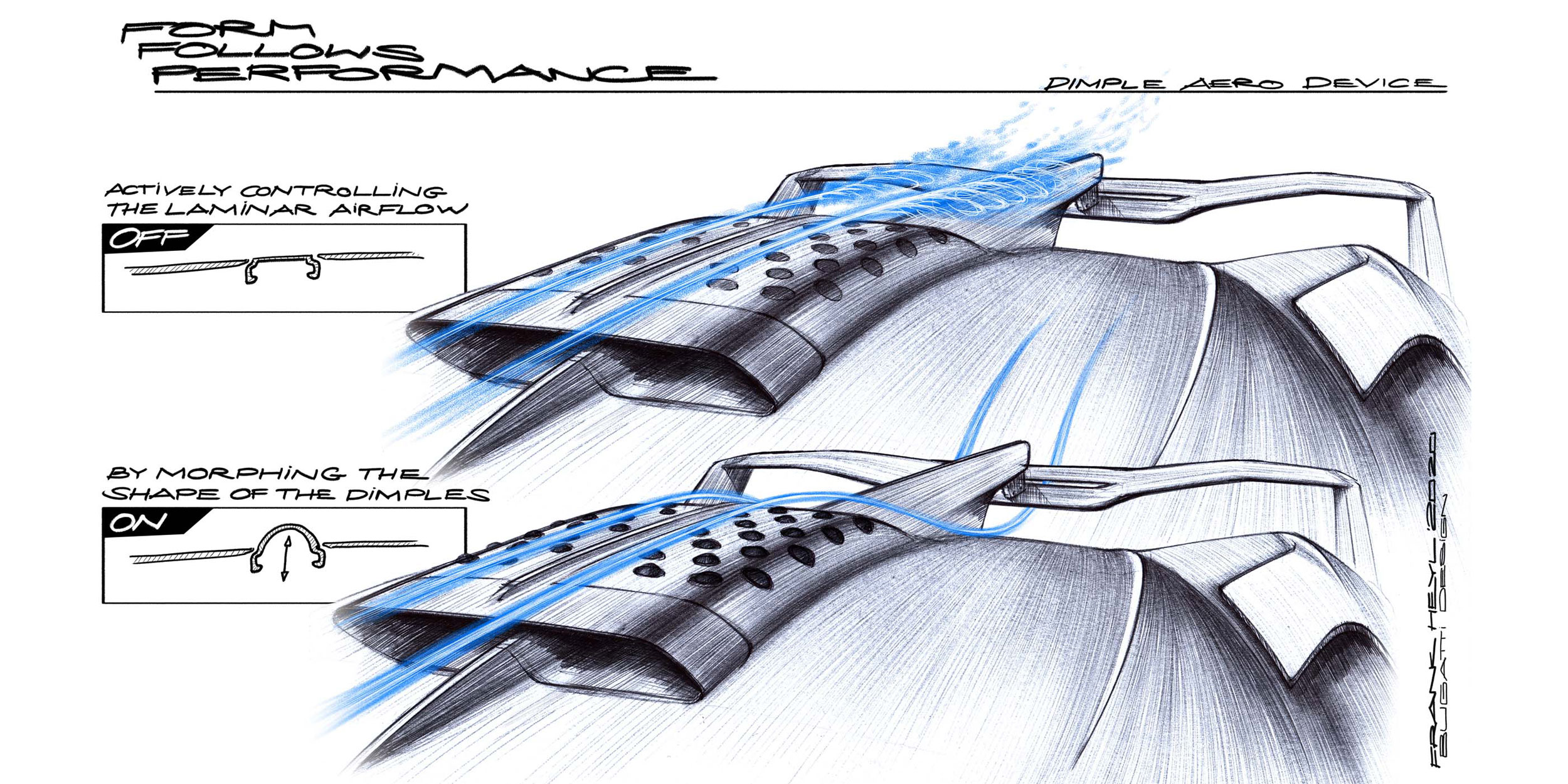

The morphable outer skin of the intake scoop on the roof is a world first: it ensures active airflow optimisation. When the vehicle is driven at a slow speed the surface of the scoop remains smooth, but at fast speeds a field of dimples bulges out. The 60 individual elements extend variably by up to 10 millimetres depending on the speed – if this benefits the driving state. From about 80 km/h upwards, air is the dominant resistance factor, and from about 120 km/h upwards the dimples significantly improve the car’s aerodynamics by reducing this resistance. As with the golf ball, the pattern causes a more turbulent boundary layer, which means that the air flowing around it adheres to the surface for longer and does not detach until later. As a result, the detachment and recirculation areas are reduced and the car’s cd value decreases. In order to respond swiftly to changes in speed, the dimples extend and retract very quickly, within tenths of a second, in the same way as the active rear wing on the Veyron and the Chiron, for example.

Ten percent less drag

The overall result is that the dimples reduce the aerodynamic drag of the scoop by 10 per cent and cause a 17 percent decrease in lift4. Airflow to the rear wing is also optimised; at 320 km/h, the downforce on the rear wing is 1,800 kilograms while on the front wing it is 800 kilograms4. Another benefit is that the lower aerodynamic drag also reduces the vehicle’s fuel or energy consumption. “This is why the new technology is so crucial – not just for Bugatti,” explains Nils Ballerstein. Optimised airflow can save energy on all vehicles, he says. “We’re still in the development phase, but tests so far show that dimples improve aerodynamics, thereby reducing drag and increasing efficiency,” adds Ballerstein.

“The Bugatti Bolide is indisputably the absolute culmination of automobile construction based around a combustion engine. In addition to the unique combination of 1,850 PS and 1,240 kilograms of dry weight, it is the multitude of technical innovations that define the concept of this racetrack-compatible hyper sports car – and it is precisely this consistently impressive level of innovation that Bugatti has proactively embraced for more than 110 years,” says Frank Götzke.

1 Fuel consumption, l/100km: this is a concept study and therefore not subject to Directive 1999/94/EC

2 When using 110-octane racing petrol; engine power with 98-octane petrol is 1,600 PS

3 The weight specification is based on the theoretically possible dry weight

4 Simulated figures