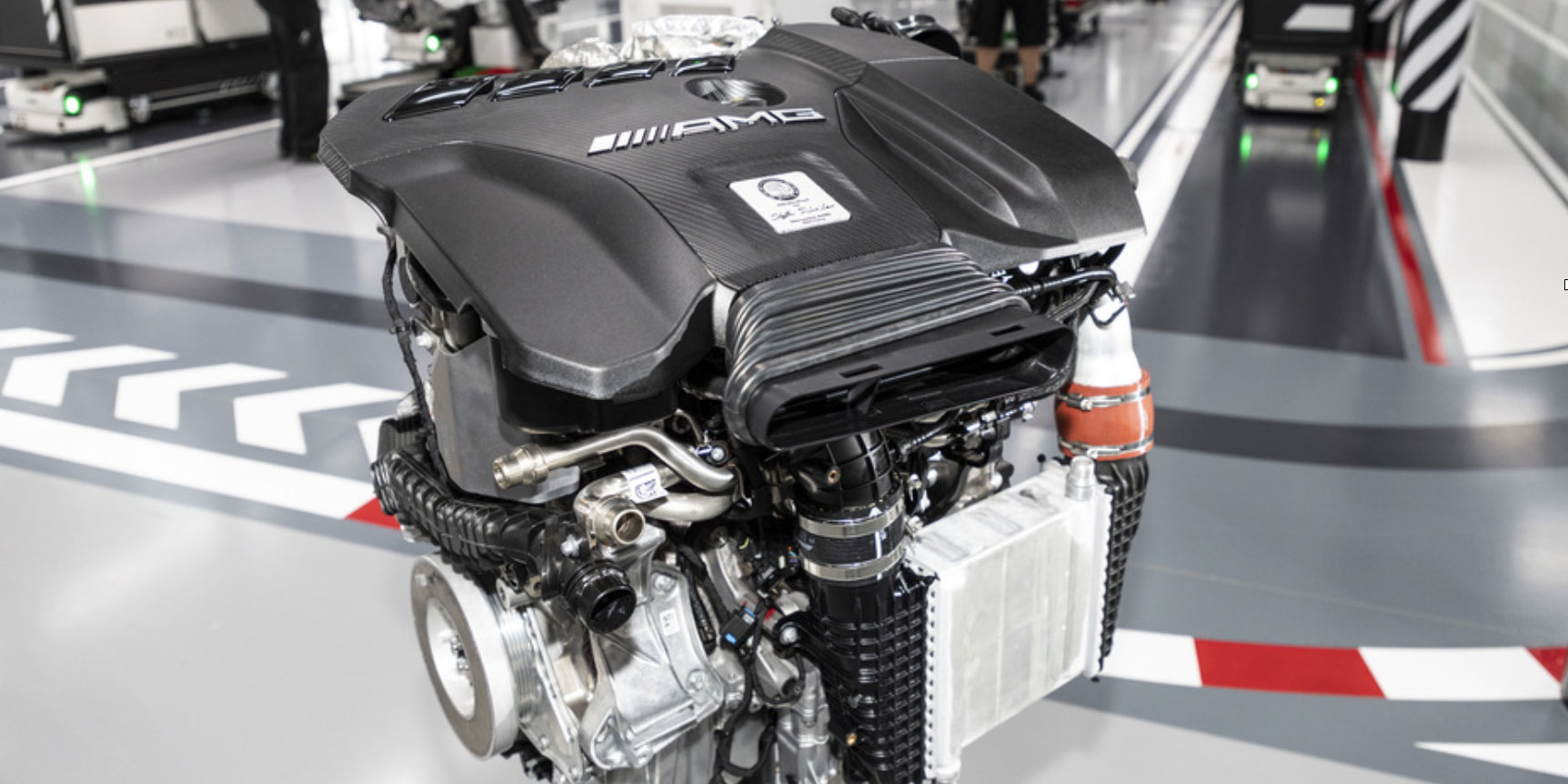

The world's most powerful four-cylinder engine in series production, made in Affalterbach

NEW MERCEDES-AMG FOUR-CYLINDER TURBO ENGINE FROM ULTRA-MODERN PRODUCTION

Affalterbach. With an output of up to 416 hp, the completely newly developed Mercedes-AMG 2.0-liter M 139 engine is the world’s most powerful turbocharged four-cylinder engine in series production. With this engine, Mercedes-AMG has even exceeded the previously most powerful M 133 engine by 40 hp. Maximum torque has also increased from 350 to up to 369 lb-ft. With an output per liter of up 208 hp, the new Mercedes-AMG high-performance turbo engine even ranks ahead of many well-known supercar engines. The new, highly efficient engine is produced on an innovative production line in Affalterbach, on the “One Man, One Engine” principle.

The four-cylinder engine is available in two output versions for the compact models of Mercedes-AMG: with 416 hp for the S-model and 382 hp in the base version. This product policy logic has already proved successful in the V8- powered AMG Performance models, and more closely meets customer wishes.

Apart from its performance figures, the new engine impresses with its immediate response. To this end, the torque curve was carefully balanced with “torque shaping”: The peak torque of 369 lb-ft (354 lb-ft for the base version) is available in a range of 5000-5250 rpm (4750-5000 rpm in the base version).

With this configuration, the AMG engineers have achieved a power delivery similar to that of a naturally aspirated engine for an even more emotional driving experience. The engine developers were also able to realize a dynamically increasing torque curve in the lower engine speed range, thereby improving agility. The increasing torque at higher rpm makes the engine more free revving. Moreover, the high maximum engine speed (up to 7200 rpm) confirms the M 139 as a sports engine.

“We already set the benchmark in the segment with the preceding engine. This fundamentally new four-cylinder presented us with the challenge of doing even better. And we succeeded with a number of sometimes revolutionary solutions. With the M 139, we have once again impressively demonstrated the engine expertise of Mercedes-AMG. Not only is the output per liter unrivalled for a turbocharged engine, the high level of efficiency also demonstrates that the internal combustion engine still has further potential,” says Tobias Moers, Chairman of Mercedes-AMG GmbH.

Why “One Man, One Engine” was reinvented

The new engine is entirely assembled by hand. On the first floor of the AMG engine manufactory in Affalterbach, a completely newly designed production line was installed in which Mercedes-AMG has brought the “One Man, One Engine” principle to a new level, together with Industry 4.0 methods that incorporate the latest findings in ergonomics, materials handling, quality assurance, sustainability and efficiency. On the road to implementing Industry 4.0, AMG’s hand assembly operation likewise follows the vision of “smart production”. This excels with maximum flexibility, and is transparent and highly efficient. It safeguards and improves the quality of the engines and production processes using innovative and digital technologies.

“We have completely revised the principle of “One Man, One Engine” for assembly of the M 139. The result is an ultra-modern production process that places the focus on people. To achieve this, we created the ideal working conditions in a bright, precisely organized and clean environment for our employees. This provides the best basis for continuing to ensure our high quality level even as the technology becomes more complex,” says Emmerich Schiller, COO and member of the Board of Management at Mercedes-AMG GmbH.

Why a 180-degree rotation brings many advantages

The new engine excels with numerous intelligent design features. Compared to the transversely installed M 260 four-cylinder in the “35” models or the preceding M 133 engine, the new Mercedes-AMG M 139 is rotated around its vertical axis by 180 degrees. This means that the turbocharger and the exhaust manifold are positioned at the rear, on the side of the firewall when viewed from behind. The intake system is therefore positioned at the front. This configuration allows the flattest possible and aerodynamically advantageous front section design. Furthermore, the new arrangement allows for improved air ducts with shorter distances and fewer diversions – both on the intake and exhaust side.

How roller bearings improve the responsiveness of the turbocharger

The new twinscroll turbocharger combines optimum responsiveness at low engine speeds with a high power in the upper rpm range. In addition to this, the turbine housing is divided into two flow passages that run parallel to one another. Together with the divided ducts in the exhaust manifold, this makes it possible to feed the exhaust flow to the turbine separately.

The aim is to prevent the individual cylinders from influencing each other negatively during load cycles, and to improve the gas cycle. The result is higher torque at lower engine speeds, and extremely quick responsiveness.

Furthermore, the shafts of the compressor and turbine have roller bearings for the first time – similar to the top output variant of the AMG 4.0-liter V8 engine in the AMG GT 4-door Coupe. The roller bearings reduce mechanical friction within the turbocharger to a minimum. The charger therefore responds more readily and reaches its maximum speed of up to 169,000 rpm more rapidly.

How electronic charge pressure control optimizes responsiveness

With a maximum charge pressure of 2.1 bar (1.9 bar in the base version), the 2.0-liter turbo engine is also a top performer in this respect. The electronically controlled wastegate (exhaust relief valve) allows the charge pressure to be controlled even more precisely and flexibly while optimizing responsiveness, especially when accelerating from partial load. Numerous parameters are taken into account in this process.

The main input signals for the wastegate control unit are the charge pressure, throttle flap position and the knocking tendency. The modifying signals include the intake air temperature, engine temperature, engine speed and atmospheric pressure. This also makes temporary boosting of the charge pressure (overboost) possible under acceleration.

Fresh air is used in addition to oil and water to cool the turbocharger. This is directed specifically to the charger from the radiator grille, via the engine cover designed as an air deflector and ducts beneath the hood.

The concept is based on the principles and experience gained with the cooling for the internally mounted turbochargers of the current AMG 4.0-liter V8 engines, starting with the AMG GT in 2014. In addition, the turbine housing incorporates integral insulation.

The advantages of the crankcase

The all-aluminum crankcase is a chill-cast unit, which excels with outstanding material properties. In this process, the molten aluminum is poured into the metallic mold. Thanks to its good thermal conductivity, the water-cooled mold allows rapid cooling and solidification of the melt. The result is a fine-grained, dense structure that guarantees very high strength. Complex interior geometries can be realized with the help of enclosed sand cores.

The closed-deck construction – a design from motor racing – ensures outstanding rigidity with low weight, and allows peak combustion pressures of up to 160 bar. The areas around the cylinders are mostly solid; only smaller ducts for the coolant and engine oil penetrate the cover plate. The crank assembly with a lightweight, forged steel crankshaft and forged aluminum pistons with optimized piston rings combines low friction with high strength. The maximum engine speed is 7200 rpm, and peak output is developed at 6750 rpm. The sump features baffle plates so that despite the larger sump, and even under high lateral acceleration forces, there is always sufficient engine oil to lubricate all the relevant components.

Why the cylinder liners are coated with NANOSLIDE

To reduce friction between the pistons and cylinders, the linings are coated using patented NANOSLIDE technology. This gives the linings a mirror-like surface for minimal friction, is twice as hard as conventional grey cast-iron liners and therefore makes them much more durable. NANOSLIDE was developed by Daimler AG, and is protected by more than 90 patent families and more than 40 patents. The coating was first used for AMG’s M 156 engine, has benefitted further AMG engines for many years and can also be found in the Formula 1 engine of Mercedes-AMG Petronas Motorsport.

How larger exhaust valves ensure faster gas cycles

Repositioning and slightly angling the injection nozzles and spark plug system in the cylinder head made it possible to enlarge the exhaust valves compared to those of the preceding M 133 engine. The larger exhaust cross-sections allow the gases to stream out of the combustion chambers with low losses, and reduce the overall piston venting action.

More efficient cylinder head cooling was achieved by seating rings with a reduced installed height and a cooling borehole near the combustion chamber, in the web area between the exhaust seating rings. The cooling performance was also improved by a near-surface water jacket geometry, a faster flow rate and an optimized volumetric flow rate.

A multi-layered, state-of-the-art corrugated metal seal isolates the cylinder head from the crankcase.

Two overhead camshafts control the 16 valves via weight-optimized roller cam followers. Camshaft adjustment on the inlet and outlet side allows an excellent response and optimizes the gas cycle for each operating point. Variable CAMTRONIC valve control on the exhaust side is another feature, with two cams per valve. The cams have different geometries, so that depending on the cam setting to suit the driving situation, the exhaust valves can be opened for short or long periods – for even better responsiveness at low engine speeds, comfortable and fuel-efficient driving at medium rpm and full power delivery in the upper rpm range.

How the fuel injection combines the best of both worlds

Turbocharging and direct injection with a spray guided combustion process not only allows for a high power yield, but also improves thermodynamic efficiency and therefore reduces both fuel consumption and exhaust emissions.

For the first time, the new high-performance four-cylinder has two-stage fuel injection. In the first stage, the particularly fast and precisely operating piezo injectors supply fuel to the combustion chambers at a pressure of up to 200 bar. This is a multiple process at times, and is controlled by the engine management system as required.

In the second stage there is additional intake manifold injection using solenoid valves. This is needed to achieve the engine’s high specific output. The electronically controlled fuel supply has an operating pressure of 6.7 bar.

How the sophisticated cooling system increases power

The high output requires an intelligently conceived cooling system. An additional radiator in the wheel arch supplements the large unit in the front level of the main module. A low-temperature circuit is also used for air/water intercooling. Together with the intercooler connected in series, a high- performance electric pump assists the coolant flow through the radiators. This provides for ideal cooling of the highly compressed charge air, thereby contributing towards optimal engine performance.

Cooling of the transmission oil is integrated into the engine’s coolant circuit, and is assisted by a heat exchanger mounted directly on the transmission. The engine control unit is mounted on the air filter housing, where it is cooled by an airflow.

Why the electric water pump brings numerous advantages

The demand-controlled, electric high-performance water pump operates independently of the engine speed. Late activation during warm-up means that the engine block warms up more rapidly, with a positive effect on friction, consumption and emissions. The pump can also be switched on or off as required when driving under less power or at low engine speeds. Furthermore, the electric water pump ensures the full engine output and optimum heat dissipation over the entire engine speed range. It also protects against thermal damage when idling in very high ambient temperatures.

Functions such as alternator management, the ECO start/stop function with fast restarting, the gliding function and a gas particulate filter are also part of the technology package for the new AMG four-cylinder.

How the new process makes work easier and improves efficiency

The new AMG 2.0-liter turbocharged four-cylinder engine with the in-house designation M 139 is assembled entirely by hand following the traditional AMG principle of “One Man, One Engine” – but with a completely new, digitally supported process and logistical organization.

People are the main consideration in all activities. The employees are assisted in their work by digital tools. The focus is on the use of intelligent, flexible technology. The key element in this modern production process is a combination of highly flexible line assembly and preconfigured shopping carts using driverless transport systems. The aspect of sustainability was also a fundamental part of the planning for the new M 139 production line.

Production uses renewable energy sources, and considerably reduces CO2 emissions, water consumption and waste.

How the new assembly cart makes work easier

The assembly cart on which the M 139 is put together was developed with the employees working as a team. It has its own, independent power supply and therefore needs no power cables. All the necessary operating fluids and tools are ergonomically arranged on and around the cart, making work easier, minimizing distances and improving efficiency. The integrated tablet PC assists the employee with precise, clearly formulated working instructions. Manuals and guidelines are a thing of the past – manufacturing is now paperless.

Why the employees call it “blue sky”

The new cordless screwdrivers are immediately to hand, and no longer need to be grabbed from overhead at each station as suspended, wired tools as before. This is why the employees refer to their workplace as “blue sky”, as there are no longer any power cables hanging from the ceiling. The assembly shop makes a bright and airy impression, and creates a pleasant working climate. Comprehensive digitization improves both the efficiency and flexibility of the manufacturing process: Each tool is connected to the WLAN of the engine assembly shop – enabling and torque settings for the relevant assembly stage can therefore be automated by indoor tracking. Furthermore, all completed tasks are digitally recorded, guaranteeing optimal quality assurance, reproduceability and transparency.

The advantages of the driverless transport systems

Each assembly technician is followed by a driverless transport system. Its shopping cart has precisely the components needed to complete the engine being assembled.

The transport systems are loaded up at the Mercedes-AMG logistical center in Marbach, and delivered to the production line on a “just in sequence” basis. Indoor tracking via WLAN also carries out autonomous control. All components are digitally tracked.

The assembly and transport carts are designed in a black-and-white Mercedes- AMG look, and carry slogans such as “START YOUR ENGINE” or “AMG PERFORMANCE INSIDE”. This contributes to motivation and identification with the company. In the same vein, the shop floor has hatching and white- and-red stripes reminiscent of the curbs and guide rails on racetracks.

Why the test stations are also more efficient

Assembly efficiency was further enhanced by reducing the number of test stations. This is made possible by grouping several individual stations into three central stations: Drag torque test, leakage test for oil/coolant and fuel systems as well as for complete engine water jacket. The result is a considerable time saving and greater efficiency. Here too, all parameters and measured values are digitally recorded and stored so that the assembly of each individual engine can be tracked.

The assembly philosophy of “One Man, One Engine” is a hallmark of the Mercedes-AMG brand. Another characteristic feature of the M 139 is therefore the AMG engine plate carrying the signature of the assembly technician. All assembly technicians for the new four-cylinder engine were given extensive further training for the M 139.

TECHNICAL DATA AT A GLANCE

| Mercedes-AMG M 139 2.0 liter turbocharged four-cylinder engine |

|

|---|---|

| Displacement | 1991 cc |

| Bore x stroke | 83.0 x 92.0 mm |

| Output | 416 hp at 6750 rpm (S-model) 382 hp at 6500 rpm (base version) |

| Peak torque | 369 lb-ft at 5000-5250 rpm (S-model) 354 lb-ft at 4750-5000 rpm (base version) |

| Max. engine speed | 7200 rpm |

| Compression ratio | 9.0:1 |

| Turbocharging | One twinscroll turbocharger with roller-bearing compressor and turbine wheels |

| Max. charge pressure | 2.1 bar (S-model) 1.9 bar (base version) |

| Mixture formation | Combined direct and manifold injection. 1.) Third-generation multiple direct injection. Fast and precise piezo injectors spray the fuel into the combustion chambers at high pressure 2.) Additional intake manifold injection with solenoid valves |

| Cylinder head | Two overhead camshafts, 16 valves, adjustable intake and exhaust camshafts, CAMTRONIC valve timing adjustment for the exhaust camshaft |

| Max. air mass throughput | 2,645 lb/h (S-model) 2,425 lb/h (base version) |

| Engine weight (wet) | 353.8 lbs |